This system centers on grid-based dense storage, combines multi-equipment collaboration and intelligent scheduling capabilities, and features modularity, high flexibility, and high fault tolerance. This system provides a highly resilient and reliable innovative warehousing solution for scenarios such as high-volume pallet storage, old warehouse renovation, and irregular warehouse layouts. This system is widely used in industries like food, fruits & vegetables, beverages, chemicals, and tobacco, which often deal with a single type of product with large batches.

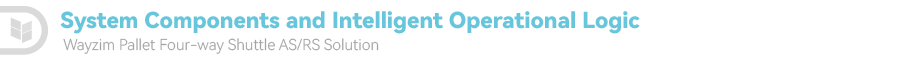

The Wayzim Pallet Four-way Shuttle AS/RS is a highly collaborative and intelligent operation system. It mainly consists of autonomous mobile robots (AMRs), pallet roller conveyors, Vertical Reciprocating Conveyors, the key components—Pallet Four-way Shuttles, and intelligent software control systems (WMS, WCS, and RCS).

*WMS: warehouse management system. WCS: warehouse control system. RCS: robot control system.

The operational logic is clear, efficient, and forms a completely closed loop. AMRs are responsible for the end-to-end connection and transportation of materials outside the warehouse, delivering pallets to the inbound dock. After precise identification by the industrial vision system, materials enter the conveyor line. The Vertical Reciprocating Conveyor conveys materials to the precise level. Finally, the Pallet Four-way Shuttle moves vertically and horizontally within rack aisles to store materials into or retrieve materials from designated locations. The outbound process is similar. The entire process operates under the unified command of the scheduling system, achieving precise, streamlined, and unmanned operations.

01 Maximized Space Utilization, Significantly Increasing Storage Density |  |

The system enables shuttles to move flexibly within a dense grid of racks, eliminating the fixed aisles required by traditional AS/RS. A more compact rack layout is possible, increasing storage density by over 20%. The system is particularly suitable for irregular factory buildings or old warehouse renovations, maximizing the use of every inch of space.

| 02 Modular Flexible Expansion, Enabling Investment to Grow with Your Busines |

The system uses a modular design separating shuttles and rails, allowing for deployment based on initial needs. As business grows, system throughput can be linearly scaled by simply adding more Four-way Shuttles or Vertical Reciprocating Conveyors. There is no need for large-scale modification of the key control system, significantly lowering the initial investment threshold and future expansion costs.

03 High-Reliability Design, Ensuring Uninterrupted Continuous Operations |  |

The system possesses high fault tolerance and rapid recovery capabilities. Multiple shuttles collaborate based on the scheduling. If a shuttle fails, its tasks are immediately taken over by another shuttle. An intelligent fault diagnosis and recovery mechanism is equipped to support automatic communication reconnection, remote reset, and manual rescue, ensuring stable 24/7 continuous operations.

| 04 Comprehensive Safety Protection for Easier Intelligent O&M |

The system builds a multi-layered safety defense from equipment to fire protection. Each Four-way Shuttle is equipped with radar devices (six in total) on all four sides for real-time obstacle avoidance, along with mechanical anti-collision and emergency stop protection devices. An innovative six-sided fireproof charging station provides physical isolation during charging and contains built-in inductive fire extinguishing devices, greatly enhancing fire safety. Besides, intelligent battery management and automatic charging strategies ensure that shuttles remain online for a long time.

Summary

The key values of Wayzim Pallet Four-way Shuttle AS/RS are dense storage, elastic expansion, intelligent collaboration, safety, and reliability. The system provides enterprises with scalable, efficient, and stable warehousing solutions through its innovative grid storage architecture and intelligent scheduling algorithms. In the process of logistics intelligence upgrading, this system is becoming a precisely targeted technological choice for high-volume pallet storage scenarios, helping enterprises to enhance warehousing efficiency and operational flexibility.

This concludes our solution sharing for this issue. For more details, please visit:

Cases: https://www.wayzim.com/en/case

We look forward to your comments: https://www.wayzim.com/en/cooperation

*Next topic: Pallet Four-way Shuttle AS/RS Solution–Key Equipment.