Industry Pain Points

As the express delivery volume has boomed, automated sorting equipment is widely used in intelligent sorting. Equipped with intelligent industrial vision systems, the automated sorting equipment enables precise sorting, reduces mis-sorting, and is suitable for sorting parcels with diverse shapes and weights.

With the wide application of smart logistics, the sorting system that has a higher demand for the equipment has presented new challenges to industrial vision systems. Traditional express delivery distribution centers and transfer centers are usually designed with small areas and limited heights, making it difficult to handle a large number of large parcels. Large parcels are usually heavy, large, and irregular, so they have professional and strict requirements for the visual recognition capability of the automated sorting equipment. In this case, relying only on human labor can cause many problems in timeliness, error rate, and cost control.

Wayzim Large Parcel 6-sided Barcode Scanning Tunnel

Solution Descriptions

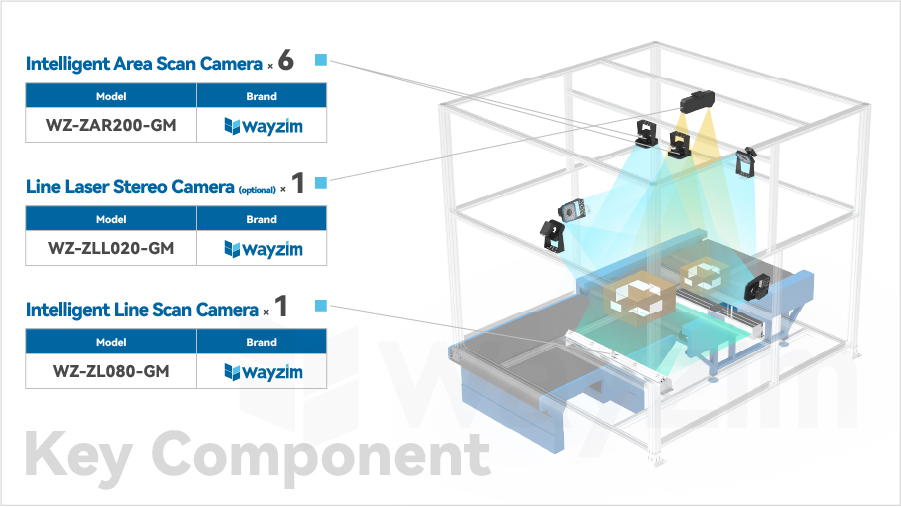

Wayzim Large Parcel 6-sided Barcode Scanning Tunnel scientifically combines barcode scanning cameras with different resolutions to enable the stable recognition of barcodes on the top, bottom, front, back, left, and right sides.

The system camera uses a built-in algorithm and a high-performance hardware processing platform. The system integrates cameras and light sources to form a compact, stable, and reliable structure. The system uses 8K line scan image fusion sensing technology to easily detect high-speed parcels. IP65 protection ensures that cameras can be used in harsh logistics environments.

Structure

Device

▲ Intelligent Area Scan Camera

Wayzim Intelligent Area Scan Camera highly integrates LED strobe light sources, the industrial lens with a large depth of field, and high-speed and high-resolution image capture components. The built-in technologies such as "horizontal and vertical barcode stitching", "super-resolution reconstruction", and "pixel-level lossless rotation” ensure that the camera can rapidly read diverse barcodes, with an accuracy of up to 99.9%. The camera supports the simultaneous reading of up to 10 barcodes at one time, with a reading speed of 120 barcodes per second.

▲ Light Source for Industrial Area Scan Camera

Wayzim industrial area scan camera light source can use high-brightness LED bulbs with different color temperatures as required. The light source lens provides light distribution angles of 40 × 40° and 60 × 60°, enabling the flexible combination of bulbs and lens. For the special applications requiring anti-reflection interference, the light source can be equipped with a diffuser to ensure that light from each direction is even.

▲ Intelligent Line Scan Camera

WZ-TL080-GM Intelligent Line Scan Camera highly integrates line scan light sources, the industrial lens, high-resolution image capture components, an embedded processor, and a control system. Based on the line scan principle, a light curtain is added to collect parcel information and capture parcel images in real time.

Solution Description

Solution Advantages

l Real-time and efficient barcode scanning

Algorithm consumption time ≤ 100 ms

l Rapid recognition speed

Support for barcode recognition at a belt speed of up to 2.3 m/s

l Recognition of diverse barcodes

Code 128, Code 39, Code 93, EAN 13, Interleaved 2 of 5 (ITF), QR code, and Data Matrix (DM) can be recognized.

l Easy to use

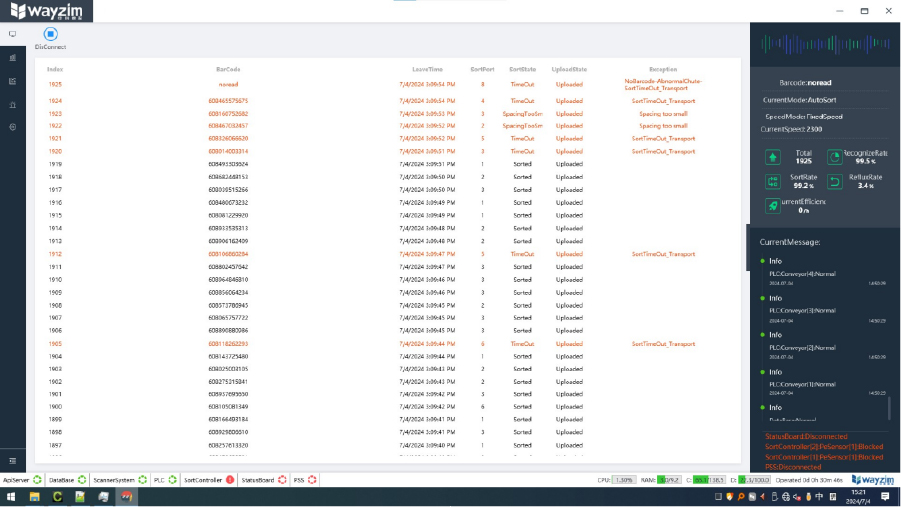

Wayzim’s proprietary barcode scanning platform features easy operations, a user-friendly screen, and robust functions, allowing custom functions tailored to different customer scenarios.

Visual Back-end Server Processing

▲ Operation

Application Cases

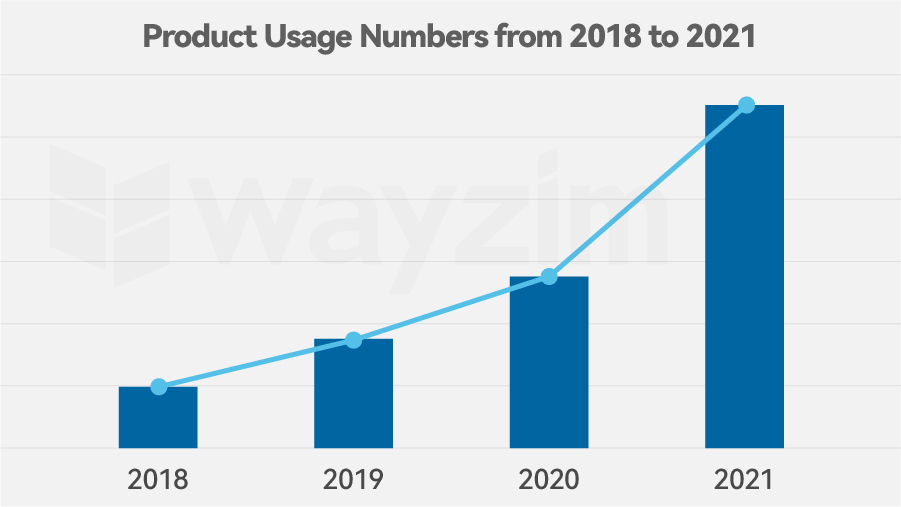

▲ Product Growth Year by Year

Since the product was launched in 2018, a total number of more than 2,400 Wayzim Large Parcel 6-sided Barcode Scanning Tunnels have been widely used by many express delivery enterprises.

In a logistic hub of the ZTO Express, the project covers an area of 60,000 ㎡. The hub was designed to operate in a fast and efficient manner to meet the throughput of the distribution center. The project also emphasized the replacement of human labor by automated and intelligent equipment as much as possible.

In response to the requirements of sorting a massive amount of express parcels, Wayzim designed and assembled devices such as conveyor lines, Pivot Wheel Sorters, and loading chutes in the project site, with the total length of the belt conveyor lines exceeding ten thousand meters. Based on the requirements, the main line was designed to operate at a speed of over 2 m/s and with a processing capacity of ≥ 3,600 pph.

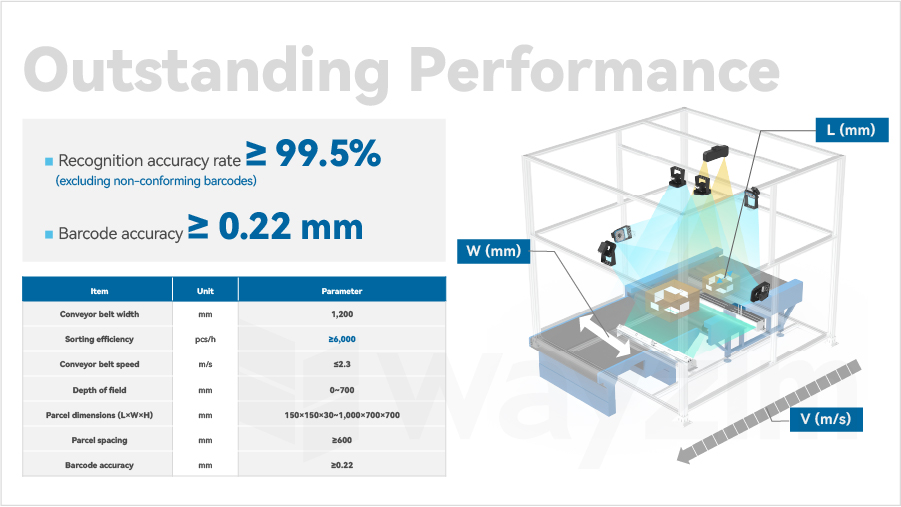

For large parcel sorting, Wayzim uses Large Parcel 6-sided Barcode Scanning Tunnels to enable the accurate recognition of barcodes on the top, bottom, left, right, front, and back sides. The system uses cutting-edge technologies in the logistics industry to support a barcode accuracy of ≥ 0.22 mm, a camera depth of field of ≥ 700 mm, a recognition rate of ≥ 99.9%, a recognition accuracy rate of ≥ 99.5% (excluding non-conforming barcodes), and a processing efficiency of ≥ 6,000 pph.

▲ Project 1

▲ Project 2