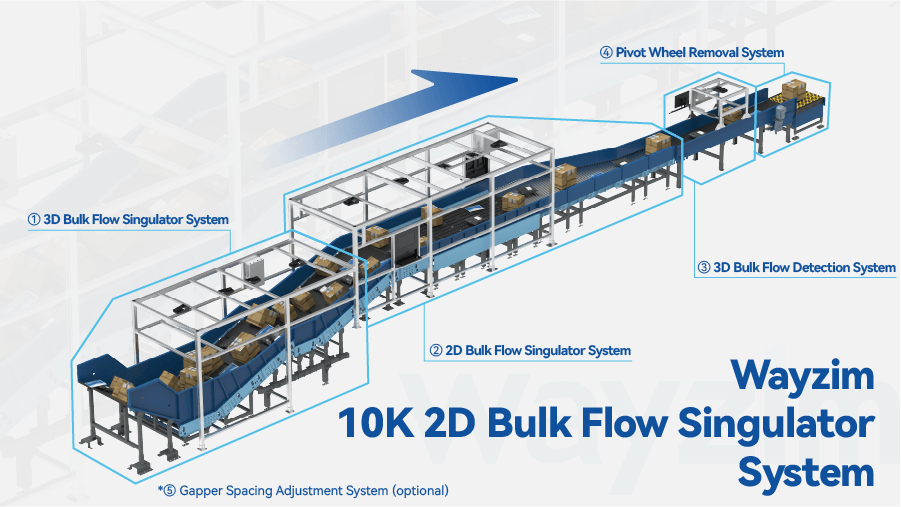

With the rapid growth of the express delivery and e-commerce business, parcel sorting exhibits a trend towards smaller parcel size, greater parcel density, and higher sorting speed. Manual sorting and infeed are inefficient and often create uncertainties in complex situations, such as workload fluctuations during peak hours and mixed parcel codes. Wayzim's 10K 2D Bulk Flow Singulator System is developed to tackle the challenge of 3D flow singulation faced by the industry. With a maximum sorting rate of 10,000 pph, this system helps provide a stable and efficient infeed environment for the intelligent sorting system through high-precision recognition, singulating/gapping, and orderly arranging of parcels.

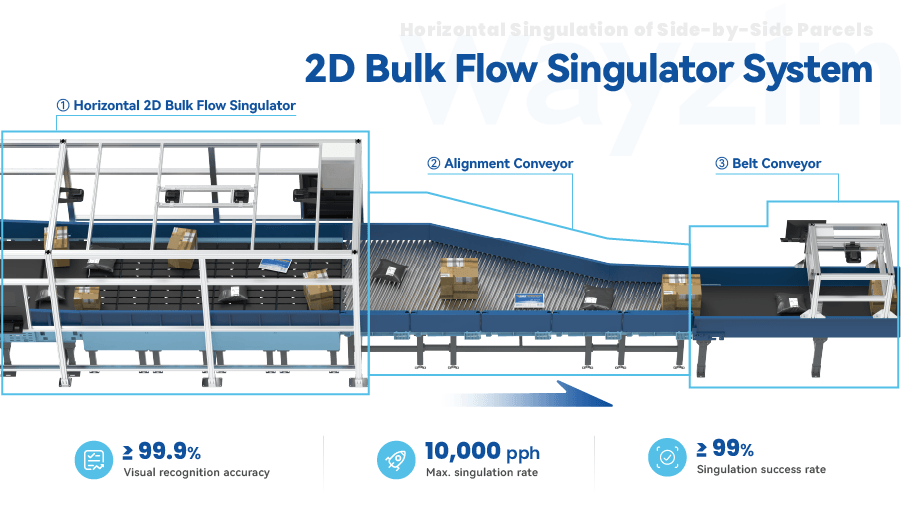

The 10K 2D Bulk Flow Singulator System consists of five subsystems, the 3D Bulk Flow Singulator System, 2D Bulk Flow Singulator System, 3D Bulk Flow Detection System, Pivot Wheel Removal System, and Gapper Spacing Adjustment System (optional). The 2D Bulk Flow Singulator System is composed of a Horizontal 2D Bulk Flow Singulator, an Alignment Conveyor, a Position Detector, and an Industrial All-in-One Camera. The entire line can operate stably at a speed of 2 m/s.

After parcels are conveyed to the 3D bulk flow singulation area by belts, the system determines the parcel positions and types through cameras, sets the parcel spacing threshold based on site requirements, and starts the intelligent control system for 3D singulation of overlaps.

After 3D singulation, parcels are conveyed to the horizontal singulation area, where the cameras collect parcel images in real time, and the vision system analyzes parcel distribution within the singulation area and controls the belt speed of each 2D singulation module according to the singulation policy to singulate side-by-side parcels.

l Horizontal 2D Bulk Flow Singulator

The Industrial All-in-One Camera collects images and uploads them to the industrial PC for algorithm-based image processing. Then, the singulator outputs the number and coordinates of parcels, and controls the belt speed of each 2D singulation module according to the singulation policy to singulate side-by-side parcels.

l Alignment Conveyor

After horizontal singulation, parcels reach the Alignment Conveyor, which consists of several non-powered rollers, and move perpendicular to the rollers until they reach one side of the Alignment Conveyor and form a stable 2D bulk flow.

l Belt Conveyor

The Belt Conveyor at the end of the 2D Bulk Flow Singulator System consists of a frame, legs, rollers, a belt, and a power system. It connects the Alignment Conveyor to the subsequent belt conveyor line.

After leaving the Alignment Conveyor, the 2D bulk flow is conveyed to the Visual Detection System for parcel position detection. If two parcels are too close to each other, the system determines that they are stacked parcels (too close). If two parcels are overlapping, the system determines that they are stacked parcels (overlaps). Otherwise, the system determines that the parcels are normal and conveys them to the next sorting section.

Stacked parcels detected by the 3D Bulk Flow Detection System are removed by pivot wheels and returned for re-sorting.

The hardware of the 10K 2D Bulk Flow Singulator System is significantly upgraded. With a wider and longer infeed section and more singulation modules in the gapping and singulation section, the system can accommodate more parcels, ensuring stable and continuous parcel output.

As a singulation module, the Alignment Conveyor uses a single row of rollers to prevent parcels from slipping during conveying, which effectively improves parcel output stability and evens the parcel spacing. The field of view is extended with the use of more cameras, increasing the accuracy and speed of parcel recognition. In addition, a servo system is used to further improve system stability and control precision.

The Industrial All-in-One Camera is equipped with backend processing devices and capable of image collection, data processing, and result output, simplifying the device architecture and reducing the requirements for backend devices. It can efficiently measure the volume of various parcels and significantly increase the image transmission and processing speed. It can also quickly transfer images to the backend system through the network port, providing stable visual data input for efficient operation of the 2D Bulk Flow Singulator System.

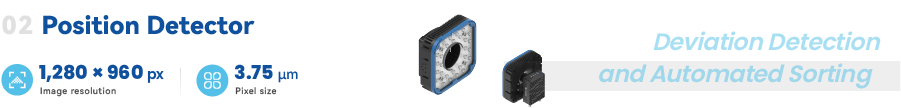

The 3D Bulk Flow Singulator System uses Wayzim's Position Detector to detect the quantity and positions of parcels. The camera integrates a high-performance hardware platform with built-in deep learning algorithms, analyzes image data in grayscale mode, and provides the five-in-one detection function, including parcel center detection, out-of-boundary detection, one-carrier-multi-parcel detection, empty pallet detection, and deviation detection. The camera can precisely detect the quantity and positions of various parcels on the conveyor line.

The Intelligent Area Scan Camera is a key component of the Large Parcel 6-Sided Barcode Scanning Tunnel. Using the deep image algorithm technology, the camera integrates an LED strobe light source, an industrial lens with a large depth of field, and a high-speed, high-resolution image capturing component. The wide field of view and depth range allow the camera to easily scan multiple barcodes at different distances.

The 3D Bulk Flow Detection Systemchecks whether parcels are properly singulated. With an RGB-D intelligent stereo camera as its core, this full-feature detection system uses deep learning algorithms to analyze image data in RGB mode and Depth mode, precisely identifying the number, positions, and types of parcels. The camera can identify various parcels such as consolidation bags, cartons, foam boxes, and soft packages, and determine the number (single or multiple) and the status (overlapping or too close to each other) of parcels.

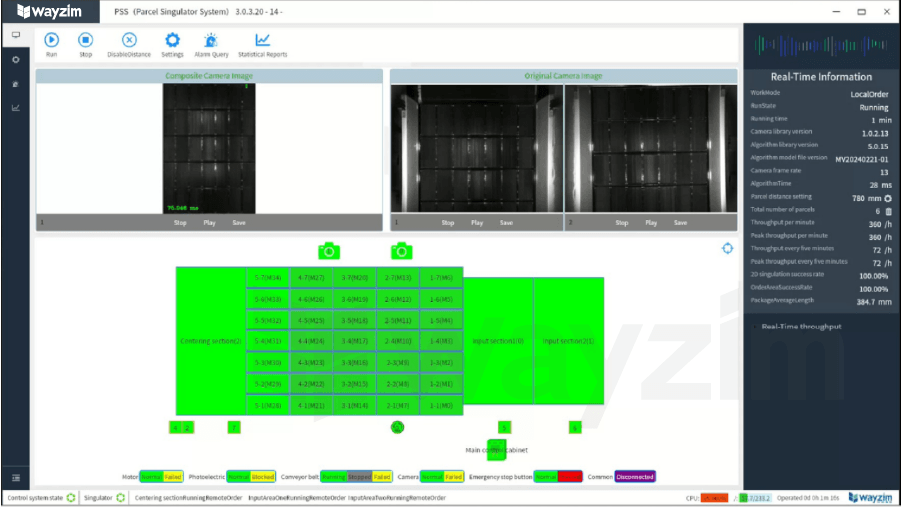

The 10K 2D Bulk Flow Singulator System uses the Parcel Singulator System (PSS) software for visualized device monitoring and management. The software displays the device status in real time and provides functions such as fault alarm, data display, parcel spacing setting, and system start/stop. It offers a comprehensive solution for operations management of the 10K 2D Bulk Flow Singulator System, greatly improving the efficiency and precision of device management.

System start/stop: The operator can easily start and stop the system with a click on the user-friendly screen.

Device status display: Different colors are used to indicate the device operating statuses, including running, delayed startup, hibernation, fault, maintenance, emergency stop, and jam alarm.

Data display: The software displays key indicators such as system throughput, singulation success rate, and average parcel length in real time to help the operator learn about the sorting efficiency.

View modes: The software provides two view modes—camera view and global view, allowing the operator to view the operating status of cameras, singulators, and servo motors in the singulation area and take prompt actions in case of emergency.

Summary

As a remarkable innovation of Wayzim, the 10K 2D Bulk Flow Singulator System has set a new benchmark for the logistics sorting sector. It addresses the challenge of efficiently sorting a massive number of small parcels faced by express delivery and e-commerce enterprises. With continuous technological upgrades and application scenario expansion, the 10K 2D Bulk Flow Singulator System will be widely used in more sectors and make its contribution to the sustained development and intelligent transformation of the logistics industry.