Project area: 4,300 ㎡ Number of pallet storage locations: 3,019, and number of tote storage locations: 9,792 The project is located in Suzhou and serves a well-known automotive parts manufacturer. To address the customer's key needs for higher storage density, fewer manual handling, and enhanced efficiency and accuracy, Wayzim delivered an integrated intelligent warehousing solution. The solution achieves full-process automation and intelligent management, establishing a highly efficient, flexible, and sustainable modern logistics center.

Number of tote storage locations

Tote AS/RS throughput capacity

Number of pallet storage locations

Pallet AS/RS throughput capacity

In conventional warehouses, a lot of space is wasted and warehouse capacity cannot be fully utilized.

Manual operations are prone to picking errors and management chaos, affecting operational accuracy and safety.

Lack of information technology support results in poor management transparency, low efficiency, and frequent manual interventions, making it difficult to meet modern logistics demands.

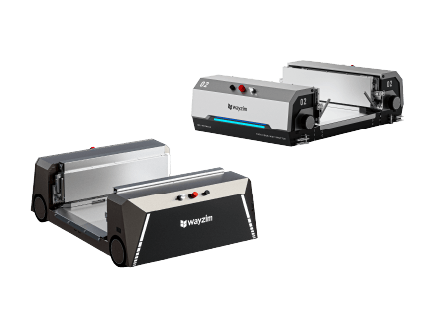

To address the customer's differentiated needs for managing small and large items, Wayzim designed and implemented two automated storage systems for this project: a tote AS/RS and a pallet AS/RS.

The tote AS/RS is dedicated to the automated storage and picking of small items, enabling fully unmanned, end-to-end closed-loop management. The pallet AS/RS handles centralized storage and inbound/outbound operations for large items. It integrates Pallet Four-way Shuttles, lifting mechanisms, and vertical conveyors to fully utilize storage space and maximize storage efficiency. AMRs serve as essential ground handling equipment, connecting various functional zones within the warehouse and enabling automated material transfer between different operational stages.

The overall solution achieves efficient collaboration among all subsystems, significantly enhancing warehouse automation, reducing operating costs, and improving the customer's supply chain responsiveness and market competitiveness.

To address space waste in conventional warehouses, Wayzim built a high-density multi-layer shelf system based on multi-layer shelves and automated storage equipment. The tote AS/RS includes 17 layers of shelves, and the pallet AS/RS includes 5 layers of shelves, with a total shelf height of about 9 meters. In this way, the vertical space can be fully utilized, the storage capacity of per unit area can be greatly increased, and warehouse pressure can be eased.

Automated equipment is introduced to replace conventional manual operations, and the computer-controlled system enables unmanned processes for inbound, storage, handling, and outbound operations. This significantly reduces errors and efficiency fluctuations caused by manual operations, improves operational safety, and builds a stable, efficient, and sustainable warehouse management model for the customer.

By using Wayzim′s in-house developed digital management platform, the system enables full-process visualization, real-time monitoring, and intelligent dispatching for goods in the warehouse. The system supports automated inventory management, dynamic task allocation, and precise picking, which efficiently reduces manual intervention, improves operational accuracy and execution efficiency, and enhances the overall digital level of warehouse operations.