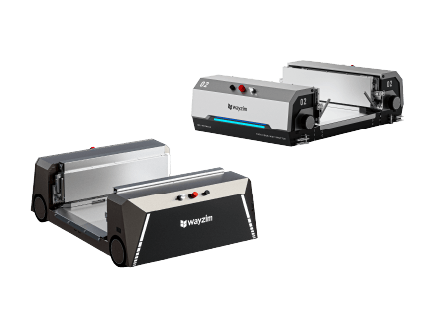

Project area: 41,025 ㎡ Number of pallet storage locations: 13,752, and number of tote storage locations: 109,250 The Hungarian AS/RS is a regional benchmark project developed to meet the rapidly growing logistics demands in Central and Eastern Europe. It serves as a large-scale, fully automated logistics and warehousing center currently operating in Hungary. To address challenges in the project's scenario, such as high-precision storage, frequent inbound and outbound operations, and limited space, Wayzim provided a customized system solution, including a Shuttle AS/RS, a Multi-level Stacker Crane AS/RS, and an high-density storage system for small parcels. The solution achieves stable operation and high space utilization under stringent operational standards.

Number of tote storage locations

Inbound and outbound efficiency

Number of pallet storage locations

Inbound and outbound efficiency

Stacker crane AS/RS storage locations

Inbound and outbound efficiency

Significant differences in product specifications lead to low efficiency in manual sorting and a long order response period.

In this bonded warehouse, high-value goods rely on manual management, resulting in high error rates and an urgent need for visualized data tracking methods.

Existing facilities and manual operations lack elastic expansion capabilities, difficult to meet high peak order processing demands.

Goods are mainly stored on flat ground or traditional shelves, resulting in loose space layout and low warehousing density and utilization.

Inventory counting is labor-intensive and time-consuming. Stock transfer counting often requires several days, affecting normal operations.

E-commerce customers need real-time parcel tracking, but the current system lacks support for in-transit weighing, barcode recognition, and real-time progress updates.

To precisely meet the customer's diverse storage needs, Wayzim designed a tailored AS/RS solution based on a customized 3D simulation. The system comprises the following components:

The Four-way Shuttle AS/RS integrates Pop-up AMRs, Vertical Reciprocating Conveyors and Four-way Shuttles to achieve high-speed pallet transfer, significantly improving storage density and inbound/outbound efficiency. The Stacker Crane High Bay AS/RS provides fully automated inbound and outbound operations on the first floor and integrates depalletizing and sorting functions on the second floor, enhancing space utilization and order response flexibility. The Tote Shuttle AS/RS utilizes pivot wheel sorting and tote shuttles for efficient small parcel processing, with manual picking and packing stations seamlessly connected to the automated conveyor system, completing the workflow through palletizing and shipping on the first floor.

This solution supports the handling of all goods types with customized storage strategies, achieving full data visualization and 24/7 automated operation. It reduces operating costs while doubling operational efficiency, enables end-to-end parcel tracking with real-time synchronization, and includes flexible space to accommodate peak demand and future expansion.

Pallet Four-way Shuttle × 26, Vertical Reciprocating Conveyor × 4, Pop-up AMR × 16, Automated conveyor lines

Stacker crane × 6, Dense shelves, steel work platform structures, automated conveyor lines, Vertical Spiral Conveyors, film wrappers, and stackers/destackers

Tote Four-way Shuttle × 100, Vertical Spiral Conveyors, goods picking conveyor line systems, pivot wheel sorting systems, and goods packing conveyor systems

Warehouse Management System (WMS) and Warehouse Control System (WCS)

For different storage units such as large parcels, hybrid pallets, and small parcels, Pallet Four-way Shuttles, Double-deep Stacker Cranes, and Tote Shuttles are configured. This supports flexible switching of inbound and outbound modes and dynamically responds to complex scenarios such as centralized inbound and outbound operations and mixed operations. The system synchronously collects information such as goods dimensions, weights, barcodes, and time to achieve full-process traceability, significantly improving material flow efficiency and system flexibility.

The roller conveyor with a large support surface is used to effectively protect goods units such as boxes and pallets, avoiding handling damage. This design ensures material safety, significantly reduces equipment wear, extends the service life of key logistics equipment, and saves maintenance and replacement costs.

By integrating the WMS and WCS, the entire process of receiving, inbound, picking, outbound, and counting is automated. The system monitors inventory status and order dynamics in real time and optimizes warehouse layout and task scheduling to improve supply chain response speed and overall operational efficiency.