Daily sorting volume: up to 40,000 pcs. Located in a key transportation and commercial hub in central England, this project addressed the rising demand for faster and more accurate parcel delivery driven by the growth of online shopping. Wayzim implemented a narrow belt sorting system solution that enables flexible speed-mode switching and simultaneous processing of various parcel types. This approach significantly improves sorting efficiency, reduces manual errors, and effectively supports expanding logistics needs.

Daily sorting volume

Sorting success rate

With the rapid growth of e-commerce demands, conventional manual sorting is struggling to handle the surge in parcel volume. Especially during the peak periods, the sorting efficiency and accuracy are difficult to maintain.

Manual sorting features low efficiency and is likely to cause manual errors when a large volume of parcels is processed during the peak periods. This not only affects delivery time efficiency but also increases logistics costs.

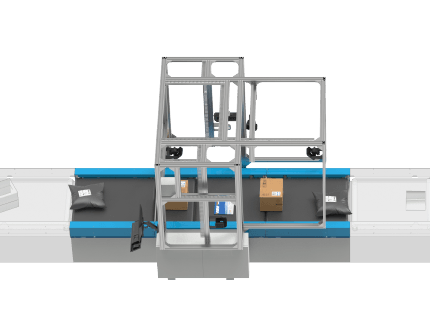

To help the company effectively meet the current sorting demands, Wayzim provided an intelligent narrow belt sorting system solution.

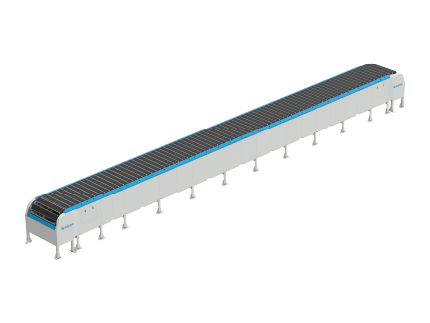

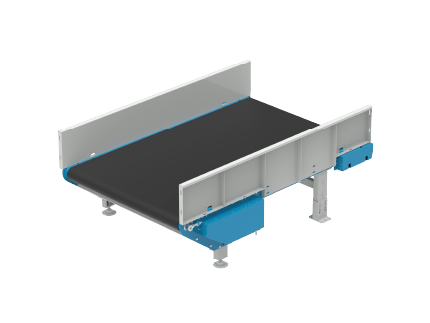

The system includes top scan cameras, belt conveyors, centering conveyors, 146 carriers, and 17 discharge points. Even during the peak periods, this system can ensure an efficient and accurate sorting process. The combination of top scan cameras and centering conveyors allows accurate and rapid parcel identification and classification, significantly enhancing sorting accuracy. In addition, the system is flexibly designed to switch speed between 1.1 m/s and 1.5 m/s.

The system can automatically adjust the speed based on different parcel types and project requirements, ensuring fast processing of parcels of various sizes and weights. The belt conveyor design includes two turning sections, which greatly reduces the equipment footprint, allows efficient operations within limited space, reduces unnecessary space waste, and further lowers operating costs.

The system′s main line is designed with two speed settings that automatically adjust based on different parcel types and project requirements, ensuring fast processing of parcels of various sizes and weights.

The belt conveyor design includes two turning sections, which greatly reduces the equipment footprint, allows efficient operation within limited space, and reduces unnecessary space waste.