Project footprint: 375 m² Daily sorting volume: 24,000 pieces (8 h) This project is in Los Angeles (the USA), which is a city known for its highly active e-commerce and international trade environment. The surging parcel volume requires higher logistics efficiency. To address the challenge of low efficiency and high labor costs in traditional manual sorting, Wayzim has developed an advanced automated sorting system. This system significantly improves sorting efficiency, reduces operating costs, and effectively helps the enterprise stand out in the fierce competition.

Daily sorting volume

Project footprint

Manual sorting is difficult to provide a higher processing speed. During peak traffic periods, such as e-commerce shopping festivals, manual sorting cannot meet the sharply increasing requirements of logistics sorting efficiency.

Errors frequently occur in manual sorting, resulting in a relatively high sorting error rate, incorrect deliveries, low customer satisfaction, and low logistics service quality.

Manual sorting requires employees to engage in strenuous handling and monotonous and repetitive hand operations. The highly intensive labor may cause much fatigue, affecting work efficiency and accuracy.

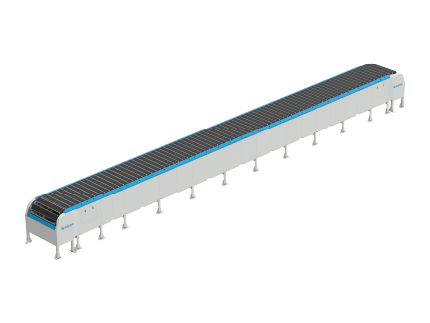

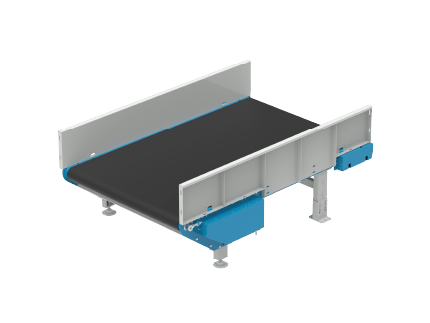

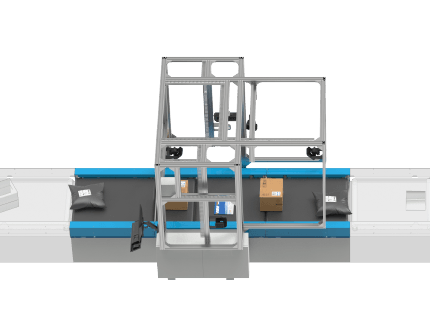

Wayzim deployed three infeed lines composed of telescoping belt conveyors and one automated narrow belt sorting line on the site. (Parcels pass through a centering conveyor, three dynamic gapping sections, the dynamic DWS system, and then the sorting line.) Compared with conventional manual sorting, this automated solution has significant advantages in improving sorting efficiency and effectively reducing operational costs.

This system uses a high-speed main line model comprising a narrow belt sorter and multiple sorting chutes to maximize space utilization, allow equipment to be highly compatible with the site, and enable automated parcel sorting. Before entering the main sorting line, parcels pass through the dynamic DWS system, which captures parcel weights, dimensions, and barcode information to allow the efficient and automated sorting of large and small parcels. Compared with conventional manual sorting, this automated sorting system reduces labor requirements and lowers overall operational costs, being an efficient, cost-effective, and sustainable sorting solution for the client.

By introducing an advanced automated sorting system, sorting efficiency has been significantly enhanced, with a daily sorting capacity reaching 24,000 items (in 8 hours).

This system employs a high-speed main line model comprising a narrow belt sorter and multiple sorting chutes to maximize space utilization, ensure high compatibility with the site, and enable automated parcel sorting.