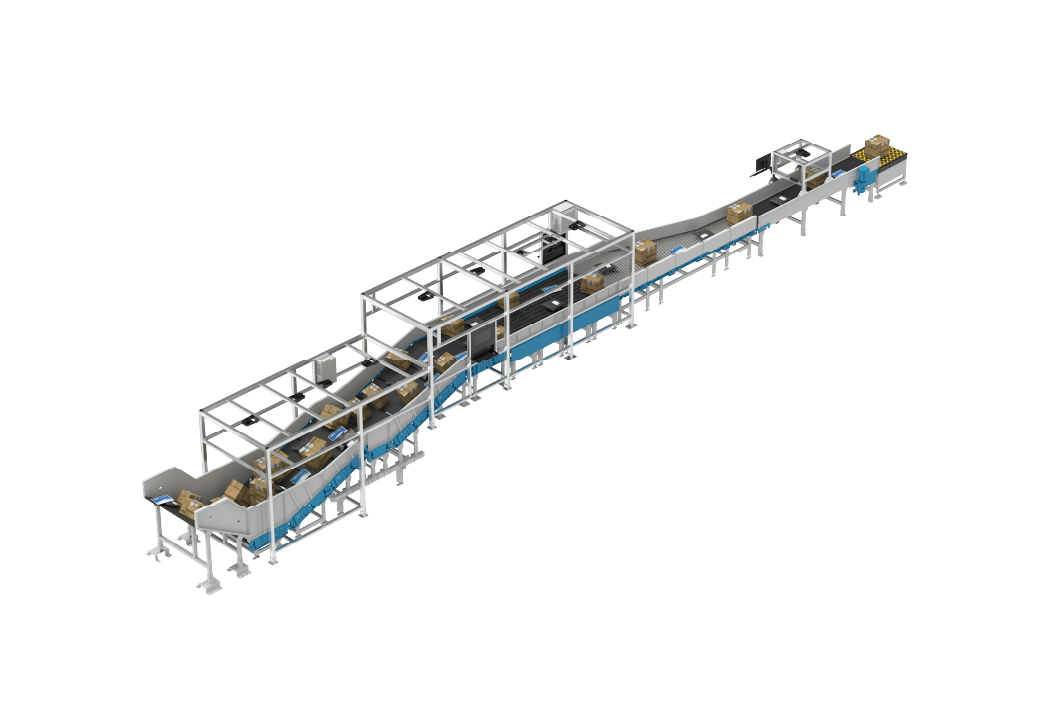

10K Singulator System

Picture-02

System Introduction

The 10K Singulator System is consists of a 3D Bulk Flow Singulator System, a 2D Bulk Flow Singulator System, a 3D Bulk Flow Detection System, a Pivot Wheel Removal System, and a Gapper (optional for spacing adjustment). The system is critical in logistics solutions, and its sorting efficiency directly impacts the overall performance of the logistics industry. This system enhances the automated processing capability for various types of parcels, from receiving and unloading, classification and removal, sorting, and loading, to distribution, through efficient 2D singulation, gap adjustment, and stacked parcel recognition and removal technologies. This system is widely used in the front-end of automated sorting systems.

Contact Us

Sorting efficiency

10,000 pph

Accuracy rate of parcel detection

≥ 99.9%

Load bearing capacity

30 kg/㎡

Product Display

Competitive Advantage

Casestudy

Competitive Advantage

Smooth singulation with fewer errors

A wider and longer input end and more singulation modules are used to allow stacked parcels to be singulated on more falling sections. The system operates with smaller gap errors and provides better handling of piled parcels.

Accurate optimization of parcel routes

Intelligent cameras and deep learning technology are used to conduct in-depth detection and calculation of parcels. The speed and route of parcels are optimized through intelligent and efficient control strategy algorithms, ensuring that the parcels are sorted and singulated in the distance required by projects.

Servo control for energy saving and stability

The entire system is controlled by a servo system, which distinguishes the system from the conventional DC motor drive method, saves energy, and enhances system stability and control precision.

Casestudy

Together Towards Tomorrow

Elevating with High-Tech Solutions

Contact Us

Make Intelligence Visible

Our Partenrs